How to Start a Mini Rice Mill Project

Rice is one of the most consumed staple foods in the world. It is also a major source of income for many farmers and millers. However, not all rice is processed in large-scale modern mills. Many small-scale farmers and households still use traditional hullers that produce low-quality rice with high breakage and impurities. To overcome these problems, a mini rice mill project can be a good option for them.

What is a Mini Rice Mill Project?

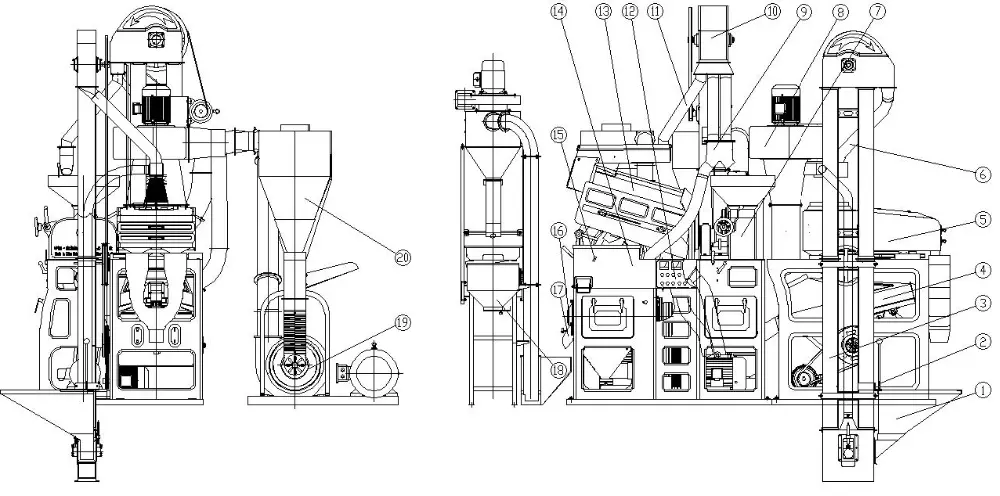

A mini rice mill project is a small-scale rice processing unit that can separate the husk and bran from the paddy and polish the rice. It can also produce pure rice bran that can be used for oil extraction or animal feed. A mini rice mill project consists of a paddy cleaner, a sheller, a separator and a polisher. The separator is based on the densimetric classification principle that separates the lighter husk from the heavier brown rice. The polisher can be either a vertical cone polisher or a horizontal rotor polisher that removes the bran layer from the rice.

A mini rice mill project can have different capacities, ranging from 150 kg/h to 2300 kg/h, depending on the model and features of the machine. It can also operate on different power sources, such as electric motor, diesel engine or solar power. A mini rice mill project can produce different types of rice, such as raw rice, parboiled rice or steamed rice, depending on the pre-treatment of the paddy.

How to Start a Project?

To start a project, you need to consider the following steps:

- Conduct a market research. You need to study the demand and supply of rice in your area, the existing competitors, the prices and quality of rice, and the potential customers. You also need to identify the best location for your project, where you can get easy access to raw materials, power supply, transport facilities and labour.

- Prepare a business plan. You need to prepare a detailed business plan that covers all aspects of your project, such as the objectives, strategies, budget, marketing plan, risk analysis and financial projections. You also need to register your business name and obtain all the necessary licenses and permits from the authorities.

- Arrange for finance. You need to arrange for adequate funds to start and run your project. You can approach banks, financial institutions or government schemes for loans or subsidies. You can also look for investors or partners who can share the risk and profit of your business.

- Purchase the equipment. You need to purchase the equipment for your project from reliable suppliers or manufacturers. You can compare different models and features of mini rice mills online or offline and choose the best one for your needs and budget. You also need to arrange for installation, testing and maintenance of the equipment.

- Hire and train staff. You need to hire and train staff who can operate and manage your project efficiently and effectively. You need to provide them with proper training on safety, hygiene, quality control and customer service.

- Promote your business. You need to promote your business and attract customers for your project. You can use various methods of marketing, such as advertising, branding, packaging, online presence, referrals, etc.

By following these steps, you can start a mini rice mill project successfully and reap the benefits of producing high-quality rice.If you are looking for a reliable supplier of Mini Rice Mill Project, contact us today. We have a wide range of models and prices to suit your needs and budget.